The Martin Technical Arc Flash Risk Assessment, Labeling, and Safety Program is one of the most comprehensive in the industry. Since 2006 our team has conducted thousands of arc flash risk assessments throughout the world for customers ranging from large manufacturing plants to companies with over 150 locations. Our combination of experience, quality, and dependability have made Martin Technical one of the premier and most trusted names in arc flash study and electrical safety. We don’t cut corners, and we put safety first!

Request a Quick Quote

Phase I – Data Collection

The first phase is the collection of field data necessary to calculate potential incident energy at power distribution equipment. Phase I can be the labor-intensive phase of the arc flash hazard study taking more than half of the total effort required to complete the analysis. Data is collected on-site by qualified persons (as defined by OSHA and NFPA 70E) in appropriate PPE; preferably assisted by a qualified facility employee or someone knowledgeable of the plant electrical equipment and facility layout.

Data collected for the study includes transformer nameplates, conductor sizes/number per phase/lengths, motors larger than 50HP, circuit breaker catalog numbers and settings, fuse catalog numbers, and on-site generator nameplates. Generally, all the data can be collected without disturbing facility operations. Proper labeling of each disconnect as to its purpose (in accordance with NEC® 110.22), is required in order to complete an accurate analysis.

Generally as part of Phase I, the electric utility will be contacted to determine the short circuit current available at the facility’s metering point.

Phase II – Power System Modeling / Electrical One-Line Diagram Development

Using the information from the Data Collection, a power system an electrical one-line diagram is developed. Electrical elements and components are shown by standard industry-accepted symbols representing each of the three phases and the connection of the power system with one line. The diagram represents the actual facility power distribution system and path from the incoming power source to all loads and equipment.

Phase III – Engineering Calculations & Arc Flash Analysis / Study

This phase is completed and/or reviewed by a licensed professional electrical engineer knowledgeable in the use of electrical engineering software, IEEE 1584 and NFPA 70E. ETAP or SKM software is used to determine the following:

Phase IV – Report Presentation

Phase IV includes delivery of the arc flash report and a brief presentation of the results of the engineering studies completed including recommended solutions for improving the electrical distribution system.

This report is accompanied by program-specific electrical one-line diagrams developed during the modeling of the system.

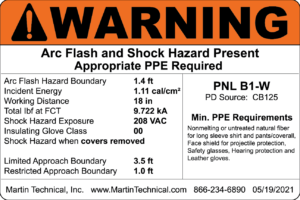

Phase V – Arc Flash Labels & Label Application

Each piece of equipment analyzed will have a printed label compliant with NFPA 70E, NFPA 70 / NEC. Labels include both arc flash and shock hazard assessment and warning to meet NFPA requirements. Labels are applied in the field by the Martin Technical technicians.

No program is complete without training to understand the results of your study and how to apply them when working on electrical equipment. Martin Technical offers several electrical safety and arc flash training programs to meet your needs.