Electrical Safety Inspections and Audits help organizations understand the safety issues and gaps in code and standard compliance associated with their plants and facilities, creating a better and safer workplace. The audit measure compliance against NFPA 70E®, NEC®, NFPA 70B® & OSHA 1910.300, and fulfills NFPA 70E requirement of conducting an electrical safety audit.

Upon completion of this program, organizations will have a clear picture of the electrical hazards or unsafe work practices that exist in their facility and a guide on how to correct them.

Request a Quick QuoteThe Martin Technical Electrical Safety Inspection and Audits focus on installations, safe work practices and electrical maintenance at your site based on the NFPA 70® The National Electrical Code (NEC), NFPA 70E®, NFPA 70B®, NFPA 79® and OSHA 1910.331-335. Per NFPA 70E, the audit shall verify the principles and processes of the electrical safety program in compliance with NFPA 70E®, the field work shall be audited to verify the requirements of NFPA 70E®, and the audit shall be documented.

This report is conducted by an electrical safety specialist who has a strong understanding of these various regulations, codes and standards, who is also field experienced in electrical plant environments.

Each site visit will entail an inspection of electrical equipment and installations to identify items from the service point of your buildings down through the feeder circuits to various branch circuits. Employees will be interviewed and work practices observed for compliance with electrical safety work practices.

There are 12 areas and over 110 points that will be investigated during the audit. The areas of investigation include:

3.2 Support for LFMC

| Rating | Item # | Description of Deficiency |

|---|---|---|

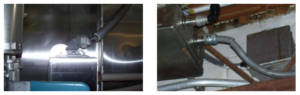

| 3 | 3.2 | Unsupported & Damaged LFMC conduit |

3.2 Observation: LFMC is improperly supported which can lead to cuts, corrosion & peeling as seen below. The NEC Code requires supporting within 12” of each box and every 4’6” after. Many areas where LMFC is used should have rigid conduit instead.