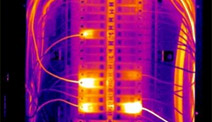

The goal of every electrical infrared (thermographic) inspection is to survey designated electrical equipment in order to pinpoint defective/damaged components and elevated temperatures within your power distribution system. If unfound or untreated these thermal “hot spots” can cause potential fire, explosion, or electrical service interruption threats. Thermal hot spots are typically caused by unbalanced or overloaded electrical circuits, loose connections, or broken/damaged equipment. These conditions are often overlooked during routine evaluations of facilities as they are not visible to the naked eye and will only be visible through infrared thermography detection services. If you suspect that your facilities’ electrical circuits are malfunctioning or are defective/damaged then an infrared or IR inspection of the facilities’ electrical system can assist in finding these anomalies. Infrared inspections should be performed every 6 – 12 months as part of the electrical preventive maintenance program.

Request a Quick QuoteA typical electrical infrared survey can in net savings from $10,000 to $20,000, depending on the number and category of anomalies found. In addition to the direct financial savings, valuable time is saved by incorporating an annual infrared electrical survey into your PM program.

Providing accurate information regarding the integrity of your electrical system’s components cuts down on maintenance time, prevents costly replacements, and can eliminate unforeseen outages and downtime. An infrared (thermal) electrical inspection survey can help:

Our certified thermographers quickly and non-destructively pinpoint electrical and mechanical problems that can not be seen with the naked eye, such as loose connections, faulty breakers, disconnects, overloaded circuits, imbalanced loads, weak motor windings and bearings, and much more. Detection of and imaging of thermal problems are done certified infrared technicians using modern thermography cameras.

During the electrical infrared survey, our team will generally inspect the following equipment but can provide inspection and imaging on any electrical or mechanical components according to your specification.

Martin Technical electrical infrared reports are concise and to the point, making anomaly locations easy to determine and facilitate repairs. Your report will include: A detailed easy-to-read inspection report including:

A report sheet accompanies each problem which includes:

Martin Technical can specify, provide and installing IR windows in your plant or facility.

Installed on switchgear enclosures and other panels, IR windows permit infrared inspections to be conducted without having to open or remove panel covers while keeping the integrity of the data collected thereby improving safety by not exposing workers to energized electrical circuits.

After completion of the infrared inspection, Martin Technical or one of our national service partners can repair defects exposed by the IR scan creating a safer and more efficient electrical equipment.

Infrared or IR Inspections should be performed every 6 months to a year to ensure the safety and optimum performance of your electrical equipment. Scheduling the inspections in both the summer heat and cold of winter provides the best results with different loads on the equipment and different ambient temperatures that may impact the equipment.

Standards that apply to Infrared Electrical System Surveys are authored by the National Fire Protection Association (NFPA) NFPA 70B and NFPA 70E, American Society for Testing and Materials (ASTM), InterNational Electrical Testing Association (NETA), and Infraspection Institute. They cover topics including frequency of inspections, process and procedures, applications, certification of personnel, equipment use and performance standards, and safety. Standards.

No. Your plant or facility won’t be disrupted by any power shut downs to complete an infrared inspection. In order to conduct an electrical infrared inspection, the equipment must be “live” and under load.