Norwalk, OH – An Ohio manufacturer faces $213,411 in federal safety fines for failures to prevent known safety hazards. Following an industrial accident at their Norwalk (OH) facility, OSHA found American Excelsior failed to develop or implement energy control procedures and also failed to train employees on energy control procedures.

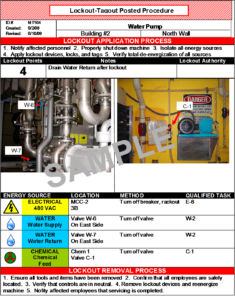

Energy control procedures, such as Lockout/Tagout, are designed to prevent unintentional machine start-up during maintenance. Lockout procedures provide detailed instruction on how to isolate and lock each energy source for a given piece of equipment, helping to prevent the startup of machinery or equipment that may result in worker injury.

In the 2018 accident at American Excelsior, OSHA investigators determined that the employee sustained injuries when a machine resumed operation while he was in the process of removing product build-up in the equipment. The worker suffered a crushed arm and required hospitalization.

According to OSHA’s Toledo Area Office Director, American Excelsior “failed to implement safety procedures to prevent known hazards…This injury could have been avoided if machine locking devices had been installed.”

OSHA’s proposed penalties of $213,411 are for violations and failures found at American Excelsior in the areas of energy control, machine guarding, and employee training.

Training employees on the value of energy control procedures is one of the most crucial pieces of a successful and compliant lockout/tagout program. Employers must provide training to ensure that the purpose and function of the energy control program are understood by employees and that they possess the knowledge and skills required for the safe application, usage, and removal of energy controls.

American Excelsior Company manufactures biodegradable erosion control blankets. They are reported to have received citations for similar violations at their Wisconsin facility in 2017 and have been placed on OSHA’s Severe Violator Enforcement Program.

Under the Occupational Safety and Health Act of 1970, employers are responsible for providing safe and healthful workplaces for their employees. OSHA sets and enforces the standards that make workplaces safe for American workers. Martin Technical is a leading provider of practical industrial safety and efficiency services. Our experts can help simplify the complex by applying real-world solutions for Lockout Tagout, Arc Flash, Electrical Safety, Risk Assessments, Training, Machine Safety & Safety Consulting Services. Contact a member of our Safety Services & Training Team to discuss how we can help make your workplace better, safer and more efficient.

Read more from original source.

We are here to help you.