Martin Technical has written hundreds of thousands of lockout tagout procedures for companies across the world in multiple languages. Our team of dedicated lockout tagout field technicians have decades of experience writing lockout procedures for every type industry, plant and facility.

Request a Quick Quote

Lockout procedures provide detailed instruction on how to isolate and lock each energy source for a given piece of equipment, helping to prevent the startup of machinery or equipment that may result in injuring a worker. Our team of certified lockout technicians and safety experts work together to provide your team with the most effective and accurate lockout program in the industry.

Procedures to be developed to isolate any prime movers with two or more energy sources. Lockout Tagout procedures are to be developed in compliance with OSHA CFR 29 1910.147, Z 244.1, or international requirements. Alternative Methods and Task Procedures can also be developed as part of the program.

Martin Technical’s RAPID LOTO™ program is a proprietary system developed by Martin Technical that allows more accurate lockout procedure development with faster turnaround time. Our professional lockout technicians use Rapid LOTO™ lockout software, and an in-field process to label equipment in the field. LOTO placards are developed and reviewed daily, keeping the information at hand relevant and fresh. Placement of the lockout placards on your equipment can often be done the next day.

Energy isolation devices such as electrical disconnect or ball valves often lack identification. Martin Technical uses in-field labeling processes to mark equipment for accurate identification of energy isolation points.

We offer a variety of labeling tags and labels to meet the most difficult environments or to match your existing system

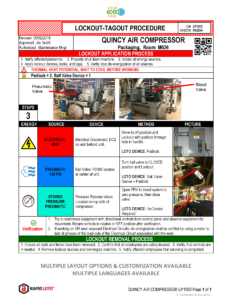

Visual energy control procedures make following the procedures simple. Our visual placards include

Lockout Tagout placards can be customized and arranged to include the data most important for you.

5 different templates types are available for different types of lockout procedures, including:

Rapid LOTO™ lockout tagout software program is used by our lockout technicians to make data collection faster and more efficient. After completion of the procedures the software can be used by customers to manage their lockout tagout program including editing & updating procedures, performing periodic inspections and doing lockout checklists.

Rapid LOTO™ lockout tagout software program is used by our lockout technicians to make data collection faster and more efficient. After completion of the procedures the software can be used by customers to manage their lockout tagout program including editing & updating procedures, performing periodic inspections and doing lockout checklists.

PHASE I – Pre-Site Visit Onboarding

Prior to coming on-site to write procedures, our team will meet with you remotely to understand your needs and equipment, select the procedure templates, and prepare your program for success.

PHASE II – EQUIPMENT & ENERGY SOURCE DATA COLLECTION

The first phase is to identify all equipment subject to LOTO regulations and the energy sources that feed the equipment. This is the most labor-intensive part of the LOTO program.

Equipment is surveyed on-site by a certified lockout tagout field technician experienced and knowledgeable of LOTO processes as well as electrical, mechanical, hydraulic, pneumatic, and thermal equipment.

PHASE III – DEVELOPMENT of LOTO PROCEDURES

Using the information from the data collection phase the procedures are developed for each piece of equipment in accordance with OSHA CFR 29 1910.147.

The procedures for each piece of equipment outline the scope, purpose, authorization, rules, and techniques to be utilized for the control of hazardous energy.

PHASE IV – CUSTOMER REVIEW

Written procedures are reviewed by team members and sent to the customer for approval printing the procedures.

PHASE V – PRINTING OF ENERGY CONTROL / LOCKOUIT TAGOUT PROCEDURES

Procedures are printed, laminated including a quality control check to make sure all procedures have been included.

PHASE VI – PLACARD APPLICATION

Lockout Tagout placards will be applied to the appropriate equipment by a certified lockout technician.

PHASE VII – LOCKOUT TRAINING & CONSULTATION

Training for Authorized employees and consultation with management providing proper information to implement the program.

Creating an efficient lockout padlock and device program is critical to the success of any lockout tagout program. Based on your environment, equipment, lockout procedures and overall needs, we can specify the right locks, locking schemes and lockout devices for your company based on our algorithms to provide the specific quantities of devices required for equipment, areas and tasks.

Creating an efficient lockout padlock and device program is critical to the success of any lockout tagout program. Based on your environment, equipment, lockout procedures and overall needs, we can specify the right locks, locking schemes and lockout devices for your company based on our algorithms to provide the specific quantities of devices required for equipment, areas and tasks.